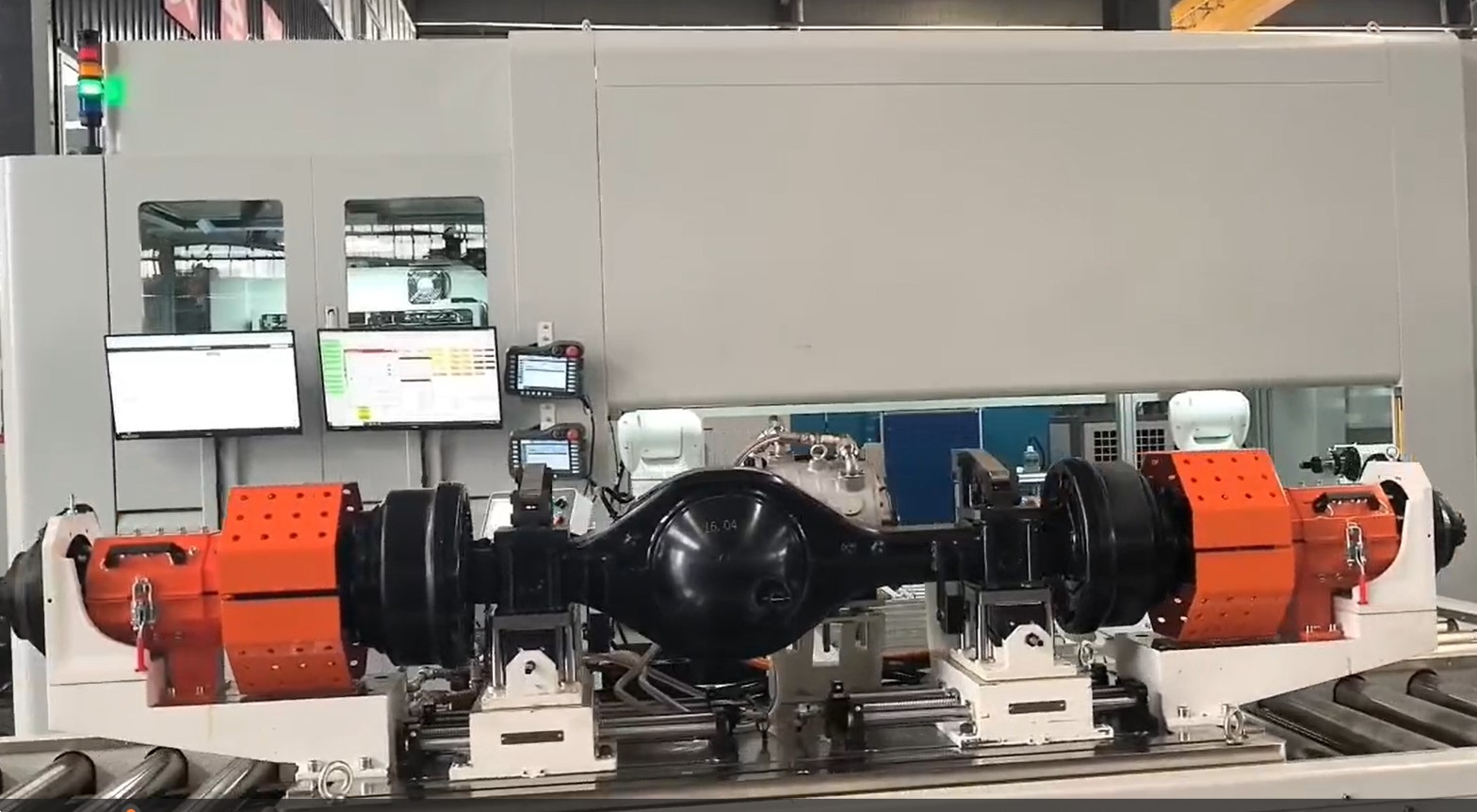

Watch Synovate‘s SigMA system in action as it conducts End-of-Line testing on NEV drive assemblies on a partner’s test bench

Watch Synovate‘s SigMA system (showcased from 00:36-00:48 in the video) in action as it conducts End-of-Line testing on NEV drive assemblies on a partner’s test bench.

1s test to qualify the product

To test for product quality, the assembled e-powertrain is subject to a 1-second NVH test on the test bench. Any early-stage quality defects in the complicated machinery could be detected with no disruptions to the pace of production.

Precision measurement enables location of defects

Unlike previously, where machinery has to be dissembled for troubleshooting, with SigMA, internal defects could be located to enable a quick and effective diagnosis.

Objective data for a deeper understanding of machinery

Best-in-class in accuracy and reliability, the large amount of data generated from SigMAnot only provides immediate insights but may also revamp the way we understand machinery.

Powered by advanced vibration signal processing technologies, the solution brings a new level of reliability to smart manufacturing, helping companies streamline quality management and ensure product health throughout the lifecycle.

Synovate Technologies is at the forefront of machine hearing technologies, integrating AI, edge computing, and cloud capabilities to provide next-gen solutions for smart manufacturing and industrial applications. With a focus on delivering high-quality data, Synovate supports clients in their transition to more considered, efficient and sustainable production processes.

For a deeper understanding of Synovate’s intelligent sensing solutions, explore the use cases to find out how Synovate is driving innovation in the industrial world.